Industrial Motor

Outstanding suction power in all conditions of use. Efficient and safe new generation induction motors.

Made to work to the extreme with several operators at the same time.

Motori industriali

Industrial Motor

Straordinaria potenza aspirante in tutte le condizioni di utilizzo. Motori a induzione di nuova generazione efficienti e sicuri.

Fatti per lavorare fino all’estremo con più operatori in contemporanea.

Discover the modular system

Infinite power

Think big and go beyond the limits. Sistem Air industrial motors go further, always.

No surface area restrictions and simultaneous use by several operators. The system is modular, built according to your needs.

Ten, a hundred, a thousand!

The beauty of a modular system is that there are no limits. Everything you need where you need it, even when the area is huge.

Even use by several operators is not a problem. Forget constraints, with Industrial Motor anything is possible.

Matic. Motors with inverter

Intelligent power delivery through electronic inverter management.

The motor automatically and continuously adjusts the suction power according to actual need. Thus only the actual energy consumption is accounted for.

Industrial motor. Tireless worker

Continuous flow and power. Maximum power for suction under constant conditions.

The absence of electronics makes industrial motors robust and suitable for working in even the most spartan environments.

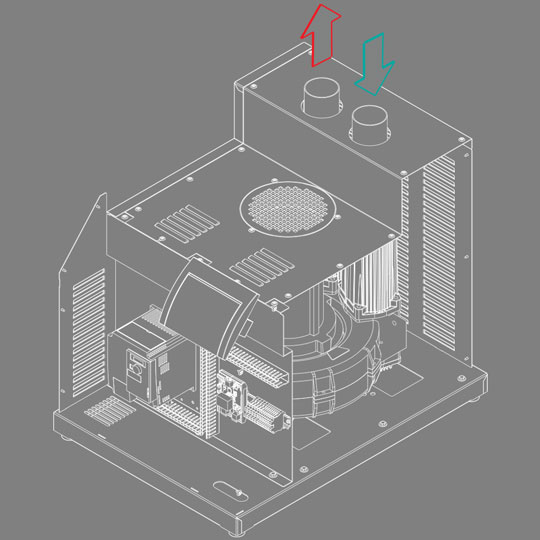

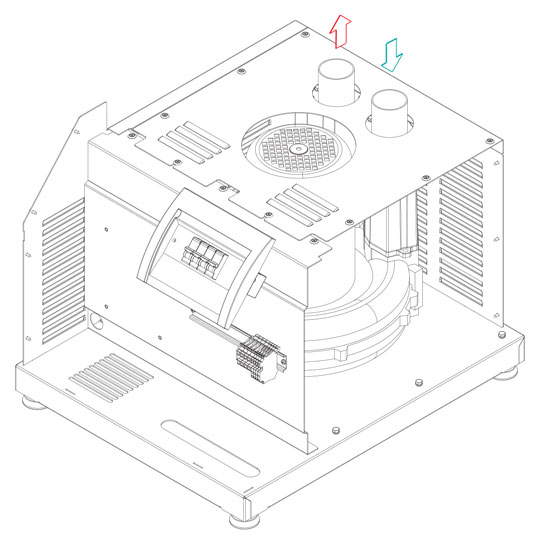

Areas of installation

Industrial Motor Matic motors have the following characteristics:

- base with epoxy powder coated metal support structure

- professional motor-pump unit in accordance with EC regulations, class IP 55, insulation class F IEC2, with integrated silencers

- side channel vacuum pump with high-performance, maintenance-free light alloy casing

- PTO thermal protector

- motor noise dB(A): 60 to 80, depending on the model and application performance

- electronic speed converter with self-ventilation and safety system to protect the unit

- 400 V general power supply

- magnetothermal protection switch on the control panel

- possibility of multiple installations, with several motors connected together

- RS 485 connection between Industrial Clean and motor-motor separator

- automatic management of starting priority in the presence of several motors.

| Model | Article | Max. no. of operators Ø 32 mm |

| Industrial Motor Matic 2,2 kW |

3503.2M | 1 |

| Industrial Motor Matic 4 kW |

3513.4M | 2 |

| Industrial Motor Matic 5,5 kW |

3503.6M | 3 |

| Industrial Motor Matic 7,5 kW |

3503.7M | 4 |

| Industrial Motor Matic 11 kW |

3503.11M | 6 |

MODULAR SYSTEM

WITHOUT LIMITS

HOMOLOGATIONS

Industrial Motor motors have the following characteristics:

- base with epoxy powder coated metal support structure

- professional motor-pump unit in accordance with EC regulations, class IP 55, insulation class F IEC2, with integrated silencers

- side channel vacuum pump with high-performance, maintenance-free light alloy casing

- motor noise dB(A): 60 to 80, depending on the model and application performance

- 400 V general power supply

- magnetothermal protection switch on the control panel

- possibility of multiple installations, with switchboard

| Model | Article | Max. no. of operators Ø 32 mm |

| Industrial Motor 4 kW |

3500.3M | 2 |

| Industrial Motor 5,5 kW |

3500.5M | 3 |

MODULAR SYSTEM

WITHOUT LIMITS

HOMOLOGATIONS

Sistem Air Pro

More than cleaning, your professional ally.

Compliance with sanitary regulations, suction of dangerous materials, waste recovery and continuous use these are just some of the pluses offered by the system SISTEM AIR PRO.

There is always need for a central vacuum system because cleaning well is an important part of the quality of your work.

Maintenance and assistance

For the scheduled maintenance of the central vacuum unit, the instructions in the technical manual provided and the instructions on the user interface display must be followed.

In particular, these periodic operations mainly concern cleaning the filter, emptying the dust collection container, replacing the bag, checking the correct operation of the electric motor and any obstruction of the air outlet.

All interventions not included in scheduled maintenance by the user must be performed by qualified workers